How To Tell If A Process Is In Control

Past Mark Durivage, Quality Systems Compliance LLC

Control charts build upon periodic inspections past plotting the procedure outputs and monitoring the procedure for special cause variation or trends. Control charts are decision-making tools that provide information for timely decisions apropos recently produced products.

Control charts can be used to identify sources of variation, both common and special crusade. Common crusade variation is the variation inherent in the process. Common cause variation is also known as the racket of the process. A process with only common cause variation is highly predictable. A procedure that has a significant inherent mutual cause variation may non be capable of producing products that see predetermined specifications. Mutual cause variation is said to account for 80% of the variation in any process and is considered management's responsibility.

Special crusade variation is variation that is non inherent to the procedure. A procedure with special cause variation is highly unpredictable. Special cause variation is said to account for 20% of the variation in whatsoever process and is considered the worker'southward responsibility.

Control charts contain a centerline — normally the mathematical average of the samples plotted — and upper and lower statistical control limits that define the constraints of common cause variation and performance information plotted over fourth dimension.

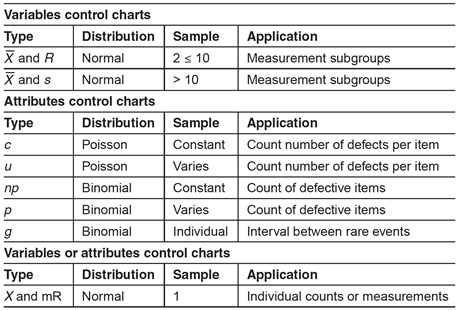

There are two full general classifications of control charts: variables and attributes charts. Variables are things that tin can be measured. Attributes are things that can be counted. The type of data (variable or attribute) will dictate the appropriate type of control chart required to monitor a procedure. Table i can be used for control chart selection.

Tabular array 1: Control Chart Option Guide

Selection of the right type of control chart is important to ensure the underlying statistical concepts are advisable for the feature or attribute beingness measured.

A process is said to be in control when the control nautical chart does not indicate whatsoever out-of-control status and contains simply mutual causes of variation. If the common crusade variation is small, then a control nautical chart can be used to monitor the procedure. If the mutual cause variation is too big, the process will need to exist modified or improved to reduce the amount of inherent variation to an acceptable level.

When a control nautical chart indicates an out-of-control condition (a point outside the control limits or matching one or more than of the criteria in the rules beneath), the assignable causes of variation must be identified and eliminated.

The following rules can be used to properly interpret control charts:

- Rule one – 1 indicate beyond the 3 σ command limit

- Rule ii – Eight or more points on one side of the centerline without crossing

- Rule three – Four out of five points in zone B or beyond

- Dominion 4 – Six points or more than in a row steadily increasing or decreasing

- Rule v – Two out of 3 points in zone A

- Rule vi – 14 points in a row alternate up and down

- Rule 7 – Whatsoever noticeable/predictable pattern, wheel, or trend

Analyzing a control nautical chart for special cause variation tin can be facilitated by using the categories used with a cause-and-result diagram. The flowing are the categories that I prefer to use:

- Equipment, Machines, and Tooling

- Surroundings

- Process

- Inspection

- Materials

- Operator

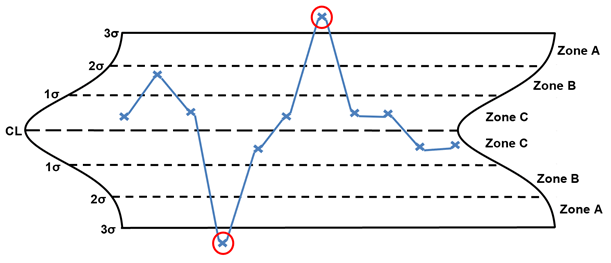

Rule 1 – One point beyond the iii σ control limit

Dominion ane, one betoken across the 3 σ command limits, seeks to identify points that are random or outliers, as shown here in red. When random or outlier points are identified, the post-obit are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper start-up

- improper setup

- sudden support organisation failure (cooling, heating, compressed air, vacuum, steam, etc.)

- tool failure/breakage

- equipment or machine failure

- improper equipment, car, and tooling maintenance

- utility intermission

- Environment

- temperature suddenly also low/high

- humidity suddenly also low/high

- Process

- equipment has non stabilized (warmed-up)

- inadequate work instructions

- missed process step

- new process

- Inspection

- inspection, measuring, and testing equipment non properly calibrated

- damaged inspection, measuring, and testing equipment

- Materials

- modify in raw materials

- change in components

- handling damage

- expired materials

- Operator

- new operators

- inadequate training

- operator interrupted or distracted

- operator overcompensating when making process adjustments

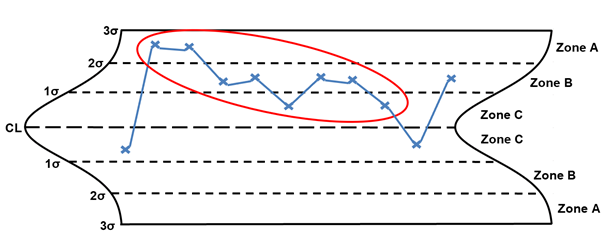

Dominion 2 – Eight or more points on one side of the centerline without crossing

Dominion 2, viii or more points on one side of the centerline without crossing, is considered a prominent shift (the shift can be on either side of the centerline). The points circled in red are considered a prominent shift. When a prominent shift is identified, the following are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper setup

- improper equipment, machine, and tooling maintenance

- damaged tooling

- tool wearable

- Environment

- temperature shifted too low/loftier

- humidity shifted too depression/high

- Process

- new procedure parameters

- incorrect process parameters

- process has improved

- process has degraded

- Inspection

- inspection, measuring, and testing equipment not properly calibrated

- damaged inspection, measuring, and testing equipment

- Materials

- change in raw materials

- alter in components

- expired materials

- Operator

- new operators

- inadequate grooming

- operator interrupted or distracted

- shift alter

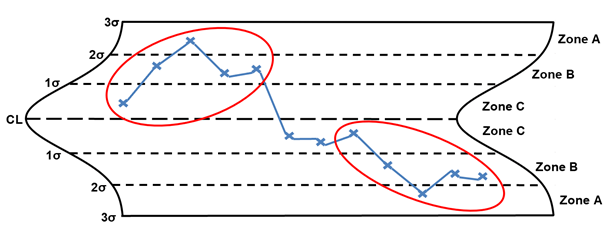

Dominion 3 – Iv out of five points in zone B or beyond

Rule 3, four out of five points in zone B or beyond, is considered a small shift (the shift can be on either side of the centerline). The points circled in red are considered small-scale shifts. When a small shift is identified, the post-obit are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper setup

- intermittent support organisation failure (cooling, heating, compressed air, vacuum, steam, etc.)

- improper equipment, machine, and tooling maintenance

- Surround

- temperature all of a sudden too low/loftier

- humidity suddenly too low/high

- Process

- new procedure parameters

- incorrect process parameters

- process has improved

- process has degraded

- Inspection

- inspection, measuring, and testing equipment not properly calibrated

- inspection, measuring, and testing equipment non acceptable for the intended employ

- damaged inspection, measuring, and testing equipment

- Materials

- mixed raw materials

- mixed components

- Operator

- new operators

- inadequate training

- operator interrupted or distracted

- shift modify

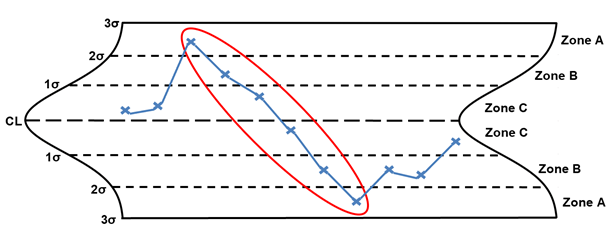

Rule 4 – Six points or more in a row steadily increasing or decreasing

Dominion 4, half-dozen points or more than in a row steadily increasing or decreasing, is considered a trend (the trend tin can be rising or falling). The points circled in ruddy are considered a tendency. When a trend is identified, the following are potential special causes to consider:

- Equipment, Machines, and Tooling

- gradual back up organization failure (cooling, heating, compressed air, vacuum, steam, etc.)

- tool clothing

- Environment

- temperature gradually drifting too low/high

- humidity gradually drifting too low/high

- Process

- process is slowly degrading

- Inspection

- inspection, measuring, and testing equipment non adequate for the intended employ

- damaged inspection, measuring, and testing equipment

- Materials

- variation in the raw materials

- variation in the components

- Operator

- operator distracted

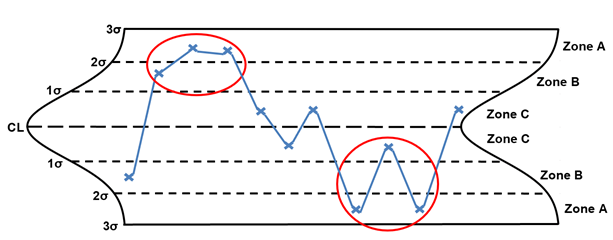

Dominion 5 – Two out of three points in zone A

Dominion 5, ii out of three points in zone A, is considered a big shift. (the shift tin be on either side of the centerline). The points circled in red are considered large shifts. When a large shift is identified, the post-obit are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper setup

- support organisation failure (cooling, heating, compressed air, vacuum, steam, etc.)

- improper equipment, automobile, and tooling maintenance

- Environment

- temperature suddenly too low/high

- humidity suddenly too low/high

- Process

- new process parameters

- wrong process parameters

- process has degraded

- Inspection

- inspection, measuring, and testing equipment not properly calibrated

- inspection, measuring, and testing equipment not acceptable for the intended apply

- damaged inspection, measuring, and testing equipment

- Materials

- mixed raw materials

- mixed components

- Operator

- new operators

- inadequate training

- operator interrupted or distracted

- shift change

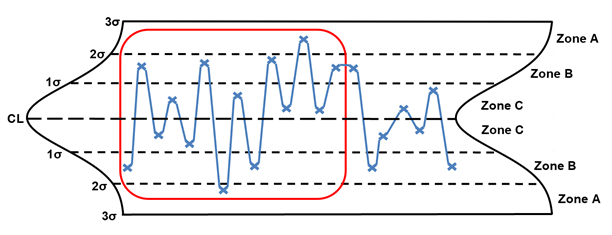

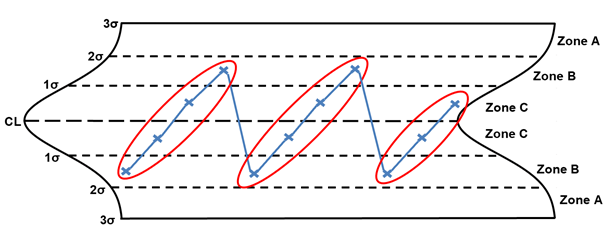

Dominion 6 – xiv points in a row alternate up and downwards

Dominion 6, 14 points in a row alternate up and down, is mostly considered to exist overcontrol. The points enclosed in blood-red are considered out of command. When this situation is identified, the following are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper setup

- intermittent back up system failure (cooling, heating, compressed air, vacuum, steam, etc.)

- improper equipment, car, and tooling maintenance

- Environment

- temperature intermittently besides low/loftier

- humidity intermittently likewise depression/high

- Process

- equipment has not stabilized (warmed-up)

- new process parameters

- incorrect procedure parameters

- inadequate work instructions

- missed process step

- new process

- Inspection

- inspection, measuring, and testing equipment non adequate for the intended use

- damaged inspection, measuring, and testing equipment

- Materials

- mixed raw materials

- mixed components

- Operator

- new operators

- inadequate training

- operator overcompensating when making process adjustments

- operator not waiting for the process to stabilize earlier making process adjustments

Please note, fifty-fifty though the operator may be over adjusting the process, at that place may exist other special causes nowadays.

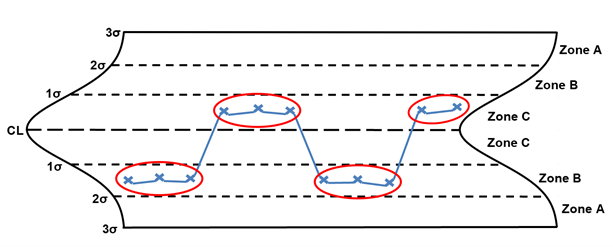

Rule vii – Any noticeable/anticipated pattern, cycle, or trend

Rule 7 is any noticeable/anticipated blueprint, wheel, or trend. The points circled in reddish are considered out of command. When these situations are identified, the post-obit are potential special causes to consider:

- Equipment, Machines, and Tooling

- improper setup

- intermittent support system failure (cooling, heating, compressed air, vacuum, steam, etc.)

- gradual support system failure (cooling, heating, compressed air, vacuum, steam, etc.)

- improper equipment, machine, and tooling maintenance

- tool vesture

- Environment

- temperature gradually drifting too low/high

- humidity gradually globe-trotting too depression/high

- temperature shifted too low/high

- humidity shifted also low/loftier

- temperature intermittently too low/high

- humidity intermittently also low/high

- Process

- equipment has not stabilized (warmed-up)

- new process parameters

- incorrect process parameters

- inadequate piece of work instructions

- missed process step

- new process

- two or more processes

- Inspection

- inspection, measuring, and testing equipment not properly calibrated

- inspection, measuring, and testing equipment not adequate for the intended use

- damaged inspection, measuring, and testing equipment

- Materials

- change in raw materials

- change in components

- mixed raw materials

- mixed components

- variation in the raw materials

- variation in the components

- Operator

- new operators

- inadequate training

- operator interrupted or distracted

- multiple shifts

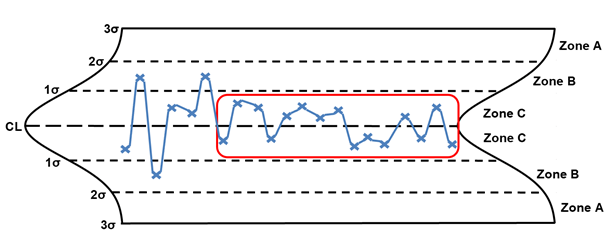

Stratification

When stratification is identified, it is more often than not due to ane of ii problems. The operators are purposefully truncating the measurements, or the process has improved significantly, which volition crave the recalculation of the statistical command limits.

Determination

It is time to consider augmenting your validated pharmaceutical, medical device, and tissue product processes, including processing, packaging, and labeling, with continuous process monitoring using control charts to ensure connected compliance with established specifications and requirements.

When implementing control charts as part of your continuous process monitoring activities, ensure the people responsible for completing the charts have been properly trained and understand the vii rules presented in this article.

I cannot emphasize enough the importance of establishing documented procedures to manage the tools and methods used. Best exercise includes providing the rationale for your organization's use of control charts for continuous process monitoring. The methods and tools presented in this article tin and should be utilized based upon manufacture practice, guidance documents, and regulatory requirements.

References:

- Durivage, M.A., 2014, Applied Engineering, Process, and Reliability Statistics, Milwaukee, ASQ Quality Printing

- Durivage, M.A., and Mehta, B., 2016, Practical Process Validation, Milwaukee, ASQ Quality Press

- Durivage, 1000.A., 2020, https://www.pharmaceuticalonline.com/doc/how-to-implement-continuous-process-monitoring-of-validated-processes-0001

Nigh The Author:

Mark Allen Durivage has worked as a practitioner, educator, consultant, and author. He is managing principal consultant at Quality Systems Compliance LLC, an ASQ Young man and SRE Fellow. Durivage primarily works with companies in the FDA regulated industries (medical devices, human being tissue, animal tissue, and pharmaceuticals), focusing on quality management arrangement implementation, integration, updates, and training. Additionally, he assists companies past providing internal and external inspect support as well as FDA 483 and warning letter response and remediation services.He earned a BAS in estimator aided machining from Siena Heights University and an MS in quality direction from Eastern Michigan University. He holds several certifications including CRE, CQE, CQA, CSSBB, RAC (Global), and CTBS. He has written several books available through ASQ Quality Press, published articles inQuality Progress, and is a frequent contributor to Life Science Connect. Yous can reach him at marker.durivage@qscompliance.com and connect with him on LinkedIn.

Mark Allen Durivage has worked as a practitioner, educator, consultant, and author. He is managing principal consultant at Quality Systems Compliance LLC, an ASQ Young man and SRE Fellow. Durivage primarily works with companies in the FDA regulated industries (medical devices, human being tissue, animal tissue, and pharmaceuticals), focusing on quality management arrangement implementation, integration, updates, and training. Additionally, he assists companies past providing internal and external inspect support as well as FDA 483 and warning letter response and remediation services.He earned a BAS in estimator aided machining from Siena Heights University and an MS in quality direction from Eastern Michigan University. He holds several certifications including CRE, CQE, CQA, CSSBB, RAC (Global), and CTBS. He has written several books available through ASQ Quality Press, published articles inQuality Progress, and is a frequent contributor to Life Science Connect. Yous can reach him at marker.durivage@qscompliance.com and connect with him on LinkedIn.

How To Tell If A Process Is In Control,

Source: https://www.pharmaceuticalonline.com/doc/rules-for-properly-interpreting-control-charts-0001

Posted by: becerrasude1962.blogspot.com

0 Response to "How To Tell If A Process Is In Control"

Post a Comment